How Do You Repair Crazing On A Shellac Finish On Furniture

Since I began my custom refinishing business, I've been amazed by the number of requests I've gotten for help with repairing scratched clear coats on dining tables, coffee tables, etc.

It is a relatively easy job, but at the same time, it's a little intimidating. Especially on an expensive piece.

Which is completely understandable! Wood tables are the centermost gathering place in your home. You're nervous to be without them for too long. And, of course, you don't want to screw the table up worse than it already is!

So today I will discuss repairing damaged clear coats. More specifically; lacquer, shellac, varnish, and polyurethane finishes. I will help you first – identify the clear coat your piece has– and second – repair each of those clear wood coats.

Related: Applying Polyurethane Perfectly | Oil-Based or Water-Based Polyurethane

Lacquer, Varnish, Polyurethane, and Shellac are the 4 most common clear coats found on wood tabletops.

It's also becoming more and more common to find waxes on wood furniture pieces. Wax doesn't provide anywhere near the protection as the finishes I'll be discussing today, but some people do use it alone to seal stained wood pieces.

Wax can be used, but I'd recommend using it only for polishing a completely dry film coat.

Wax applied on top of other clear coats like lacquer or shellac, helps to polish it up nicely. Although it needs to be reapplied over time, it's actually a nuisance to completely remove.

Always check for wax, and remove it, before applying any solvents to your piece to figure out which clear coat you have.

Related: Antique Wax Glaze on Chalk Paint

If you can scratch the clear coat with the back of your fingernail or a coin, without much effort, there is probably wax on it. Clean the wax off with mineral spirits before attempting to identify which clear finish you have.

DO NOT sand the piece if there's wax on it.

It will not remove the wax, only spread it around more, and push it deeper into the surface of the wood. It's difficult enough to remove wax completely from wood, don't make it harder on yourself!

Use lots of clean rags and mineral spirits, changing frequently. If the rag feels waxy, it's most likely spreading wax around on your piece even more. Change to a fresh one to avoid this annoyance.

Once you know your piece is free from wax, you can perform a pretty simple test to narrow down your clear coat.

You'll need 3 things:

Lacquer Thinner

Denatured Alcohol

Xylene

Be sure to test your piece in the exact order I have here. Some solvents work for multiple finishes, so this order is the best way to narrow it down correctly.

How To Identify Lacquer, Shellac, Varnish, and Polyurethane Wood Clear Coats.

1. Apply a drop or two of Denatured Alcohol to an inconspicuous spot on the piece. Let it sit for about 10 seconds, then check it.

– If the finish is shellac, the surface should be soft and sticky.

-If the denatured alcohol just sits on top of the finish, or nothing happens, try the next step.

2. Apply a small amount of Lacquer Thinner to a different, inconspicuous spot on the piece.

– If, after a few seconds, the clear coat softens almost to a liquid form, or is soft, sticky, or mushy, you've got a lacquer finish. If the lacquer thinner beads or sits on top of the clear coat, you've most likely got a varnish or polyurethane finish.

3. At this point, if you know it's not a lacquer or shellac finish, then you're looking at a varnish finish. Believe it or not, polyurethane is just a type of varnish.

Yes, the two are different, but it honestly doesn't matter a whole lot whether it's varnish or poly based on how you will repair it.

The only thing you might need to know is whether it's water-based/waterborne or oil. Varnish is an oil-based resin that is great for outdoor furniture. Polyurethane can be either water or oil-based. To be sure, try out the xylene.

– Apply the xylene to a different spot on your piece, and leave it on for a bit longer than the lacquer thinner or alcohol. If the area becomes sticky, you're looking at a water-based polyurethane.

– If nothing happens, you've got a varnish or oil-based polyurethane finish. Both can be repaired the same way, which I will discuss later in this article.

Once you've figured out the clear coat you're working with, you can attempt to repair it.

Each clear coat has to be repaired in its own specific way. I will explain each one separately for you next!

Before I do though, I just want you to make sure, one more time, that you only need to repair the clear coat, and not completely refinish the entire piece.

If the scratches on your piece go all the way down to the wood, you may need to sand and re-stain your piece as well as redo the clear coat.

Most often, damages to clear coat finished wood tables, are only surface scratches.

Sometimes it may even be damage to the wax or furniture polish on top of the clear coat!

If you look at the scratch from an angle, it may appear white, but the wood beneath should not have any discoloration. If this is the case, you're looking at a surface scratch.

If the wood itself looks lighter beneath the clear coat, it may also be damaged. In that case, you would have to completely refinish the table, including stripping and/or sanding and re-staining the wood.

To be completely sure the scratches are superficial, clean the surface thoroughly.

I usually try mineral spirits first-off either way. Just in case there are any waxes anywhere on the surface. Afterward, warm water and dish detergent should be sufficient enough to remove any other oil or dirt build-up on the surface.

Scrub reasonably hard. You may be surprised! More often than not, a "scratch" is just dirt or whatever "crud" happened to get stuck to the table. Be grateful if you're that lucky!

Work quickly, and don't soak the wood too much with water. Instead of pouring the water over the wood, wet a cloth and apply it that way. Too much water can cause a white haze on lacquer and shellac finishes.

If you've dried it thoroughly, and see this haze, you can try getting it off with 0000 steel wool and linseed oil.

Once the surface is completely clean, test the scratch with mineral spirits to decide it's depth.

If the scratch turns darker than the surrounding area, there is damage to the wood.

If the scratch doesn't change color at all, then it is definitely only surface scratch.

If the scratch does change color to match the surrounding area, then it's a bit deeper than the surface, but not through to the wood.

As long as the scratch doesn't turn darker than the surrounding area, you should be able to overcoat it with a matching clear coat.

If it turns out that your damages are to the wood itself, and not just the clear coat, you will need to completely refinish your piece.

Luckily, I've got some info on that too! Check out my posts on:

Stripping Paint (and other finishes)

(possibly)

Restoring Wood Veneer Furniture

How to Sand Wood Furniture

Preparing Wood For Staining

and

How to Stain Wood Furniture

Then come back to this post and complete your finish!

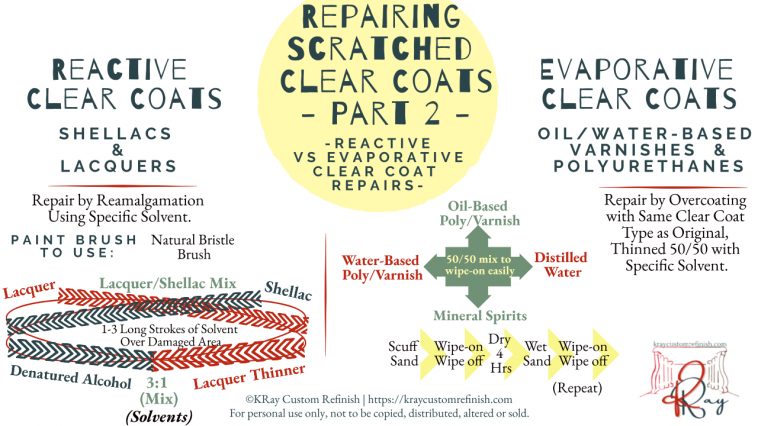

Evaporative Clear Coats vs. Reactive Clear Coats

Lacquer and Shellac are evaporative clear coats. Varnish and Polyurethane are reactive clear coats.

Evaporative clear coats harden into their final film coat, once the solvent that's used to thin it evaporates.

Lacquer's solvent is lacquer thinner, shellac's solvent is denatured alcohol.

This means that if they come in contact with their particular solvent, even after completely drying, they will re-dissolve into liquid form. This has its benefits and its drawbacks.

It certainly helps if you need to repair the clear coat. But it also makes these finishes less durable than other, reactive, clear coats.

Reactive clear coats cure through a chemical reaction.

Once this chemical reaction occurs, there is no way to reverse it. Therefore, no solvent can re-dissolve varnish or polyurethane.

Again, making it more difficult to repair, but much more durable than evaporative clear coats.

Because of these differences, it's very important, again, that you figure out which clear coat you're dealing with before attempting to repair it!

Evaporative Clear Coats:

Shellac

Lacquer

Reamalgamation can be done to repair cracks, scratches, & marks on finish only. (Not damage to the actual wood)

Reactive Clear Coats:

Varnish

Polyurethane

Overcoating with a varnish or poly to match. Reamalgamation does not work on varnish or polyurethane.

I created a nice little printable chart for you to hang up in your workspace 🙂 It will hopefully help you to remember the steps for identifying each clear coat, and what you can do to repair them! Click to get your free download.

Working on a varnish or polyurethane clear coat? Skip Ahead to learn how to repair scratched polyurethane or varnish clear coats.

Repairing a Scratched Lacquer or Shellac Clear Coat: Reamalgamation

Reamalgamation can be done on lacquer or shellac clear coats that have cracks, scratches, or have alligatored or crazed over time. Usually due to excessive sunlight or temperature changes.

If you've ever seen a clear coat that has alligatored, you'd know right away what I mean. You'll see a bunch of small, intersecting lines that resemble the rough skin of an alligator. Clever right?

Crazed clear coats are similar, but have less of a pattern than alligatored clear coats do. The lines are all over the place in a "crazed" pattern.

Either way, these little cracks are in the finish only, not the wood. Again, making the amalgamation process possible.

Amalgamation is pretty much re-liquifying the clear coat, and then letting it harden again.

It will then harden into a new, solid, flat surface, without the original cracks or scratches.

As we talked about earlier, lacquer and shellac both have their own solvents for re-liquifying.

Lacquer clear coats can be amalgamated using lacquer thinner.

Shellac clear coats can be amalgamated using denatured alcohol.

If you think your piece has both lacquer and shellac on it, you can use a mix of 3 parts denatured alcohol, to 1 part lacquer thinner.

How To ReAmalgamate a Damaged Lacquer or Shellac Clear Coat

Time Needed : 1 days 00 hours 0000 minutes

How-to Amalgamate a Damaged Lacquer or Shellac Clear Coat

- Clean the area thoroughly.

Use mineral spirits to ensure the removal of any waxes.

- Using a 100% clean, new, natural bristle paintbrush soaked in solvent, apply to the surface.

Apply it to the finish in long strokes, working with the grain.

- Go over the damaged area 1-3 times in long strokes.

Work quickly, and don't let your brush dry out. Try not to focus too much on individual spots, or you'll end up removing the clear coat.

- Allow drying for 30 minutes or more. The surface should look dull, not glossy.

As the clear finish dries, most of the cracks will disappear on their own. You may need to repeat the process to remove them all.

- If damages are still visible, repeat steps 2-4 until your clear coat is solid and smooth.

Use only a small amount of the solvent, and try your best not to remove more of the clear coat in the process.

- Once all marks have been removed, allow the finish to dry until it's no longer glossy. Then lightly buff the surface with 0000 steel wool.

Working with the grain, with medium to heavy pressure.

- If the finish seems thin, you may want to apply another coat of the same clear finish on top. Just clean the surface well with a tack cloth before applying.

Once the second coat dries, again, buff it with 0000 steel wool.

- Finally, wax the surface with hard paste wax and a clean cloth.

You can stick with the steel wool for this as well if you'd like, I usually switch over to a nice cloth. It's easier for buffing in small circular motions without worrying about scratches.

Materials

- Mineral Spirits

- Denatured Alcohol/Lacquer Thinner

It may seem simple, but reamalgamation takes some serious practice for a nice end result.

If several amalgamation attempts don't remove the damages to your piece, then the damage is probably to the wood itself.

Meaning you'll need to completely refinish it and repair the wood, before reapplying your stain and clear coat.

As I said earlier, if your piece has varnish or polyurethane on it, amalgamation won't work.

These reactive clear coats can only be overcoated to hide the damages to them. You can do small areas on the piece, or the entire surface.

Overcoating small areas on a piece is sometimes much more difficult than overcoating the entire surface.

If you choose to repair only a small spot or multiple small spots, you will have to get it to blend in with the clear coat that's already on the piece.

Clean the area with mineral spirits, or denatured alcohol to remove wax and dirt. Then lightly scuff it up with fine-grit sandpaper or 0000 steel wool.

If you're dealing with scratches that are right at the top of the clear coat, and don't go very deep at all, steel wool would be the better choice for you.

It's easy to go too deep through the finish to the wood –which you don't want to do– so sand very lightly if you plan to only do a few small spots instead of the whole surface.

Whatever clear coat your piece originally had, you will need to reapply the same on top of it.

Varnish must be overcoated with varnish, polyurethane must be overcoated with polyurethane (water or oil).

One thing that you can change to make it easier for yourself, is to make your varnish or poly wipe-on capable, by thinning it. You can purchase it, or make your own for much cheaper!

Wiping varnish/poly is much easier to apply for a smooth finish than brushing varnish/poly.

Wiping varnish/poly is thinner than brushing varnish/poly so you'll need to put on more coats when wiping it on. But I personally think that the ease of application makes up for that little fact.

All you need to do to turn your varnish or poly into a wiping version is mix in some mineral spirits if it's oil-based, or mix in water if it's water-based.

A mixture of 50/50 for the first couple of coats works perfectly. For your final coat, you may want to thicken it up to 2 parts varnish/poly to 1 part mineral spirits/water. This will make the final coat thicker and stronger.

Related: Refinishing Metal Furniture – Things to Know Before You Start

How To Repair a Damaged Polyurethane or Varnish Clear Coat

Materials Needed:

Mineral Spirits, Clean Rags, 320-600-grit Sandpaper, 0000 Steel Wool

1- Clean the entire surface with mineral spirits and a clean rag to remove any wax or dirt.

2- Lightly sand/scuff the entire area that you plan to apply a new coat on. Use fine-grit sandpaper 320 or higher. This will give the new coat something to grab onto and may blend in some of the surface scratches you're trying to repair.

Scuff Sanding Polyurethane Tabletop from KRay Custom Refinish on Vimeo.

3 – Wipe all of the dust off of the surface, make sure you get everything before applying your first coat. Try not to blow the dust into the air around your workspace if possible.

4 – Pour wiping poly/varnish onto the surface, and spread it over the area using a dry cloth.

Once the surface is well moistened, use another dry cloth and lightly wipe off any excess poly/varnish from the surface. Don't apply any pressure to the surface, just lightly dab the excess off.

5 – Let that first coat dry for at least 4 hours.

6 – Lightly sand off any dust nibs or bubbles out of the first coat with 600-grit sandpaper. I recommend using wet/dry sandpaper lubricated with water and a drop of dish detergent for this. Otherwise, the dried finish will build upon your paper pretty much instantly, causing even more damage to your finish. Once your sandpaper gets that dry finish build-up, stop!

If not, you're bound to create scratches in the clear coat you're trying to repair.

1-2 passes with the sandpaper in hand is usually sufficient. You'll be able to feel the roughness with your hand. Once it's nice and smooth you're good.

7 – Wipe off any dust with a tack cloth or you can suck it up with a vacuum. Avoid the dust getting into the air you're working in.

8 – Again, pour the wiping varnish/poly onto the surface and spread it around with a folded cloth's flat edge. Leave a little more on the surface this time than the first coat.

Continue leveling it with the folded cloth, and don't wipe with the dry cloth this time. Be sure to get it as thin and level as you can.

You can remove any excess slightly with a dry cloth, but then continue spreading with the folded cloth.

9 – Allow the coat to dry overnight, or at least 4-6 hours.

10 – Repeat steps 6-9 until the area matches its surrounding areas' thicknesses, or you are satisfied with the thickness.

11 – The final result should be glossy. If the existing clear coat doesn't match that, you can use 0000 steel wool to dull the surface, and buff with paste wax to reach the desired sheen.

And there we have it! I know I haven't even come close to covering it all when it comes to repairing damaged clear coats but for now, I'll stop here.

Lacquer, Shellac, Polyurethane, and Varnish are 4 products that come up on a day-to-day basis while refinishing furniture. All 4 are great in their own way, but not perfect that's for sure! Hopefully, I've shared with you some knowledge that will help you with future wood clear coat repairs.

I know a lot of people that jump immediately into completely refinishing a piece of furniture when the surface clear coat is scratched. That's fine, but I wanted people to know there is an easier, cheaper, and faster way. No matter the clear coat!

Recent Post: Applying Polyurethane Perfectly

Do you know of any repair tricks for lacquer, shellac, polyurethane, or varnish? Please comment away I would love to hear them!

Be sure to join my mailing list for future posts on wood finishes. And don't forget your Identifying & Repairing Scratched Clear Coats Cheat Sheet!

Until Next Time,

KRay

How Do You Repair Crazing On A Shellac Finish On Furniture

Source: https://kraycustomrefinish.com/repairing-scratched-clear-coats/

Posted by: reidfuldn1960.blogspot.com

0 Response to "How Do You Repair Crazing On A Shellac Finish On Furniture"

Post a Comment